Froth flotation enables the extraction of minerals from lower-grade ore in mining operations around the world. Additionally, froth flotation is employed in the paper recycling and wastewater industries. Like any heavy industrial application, flotation requires wear materials that stand up to wear and tear; a component that needs to be replaced less frequently can save operations time and money through less downtime and lower repair and replacement costs.

In an era of declining ore grades and increased operating costs, increased efficiency not only adds value for your stakeholders, but also keeps your operation competitive in an evolving landscape. Iracore’s flotation wear products provide exceptional durability and unbeatable value to take your operation’s efficiency to new heights. Read on to learn more about how our flotation wear components can add value to your organization.

Engineered Wear Solutions

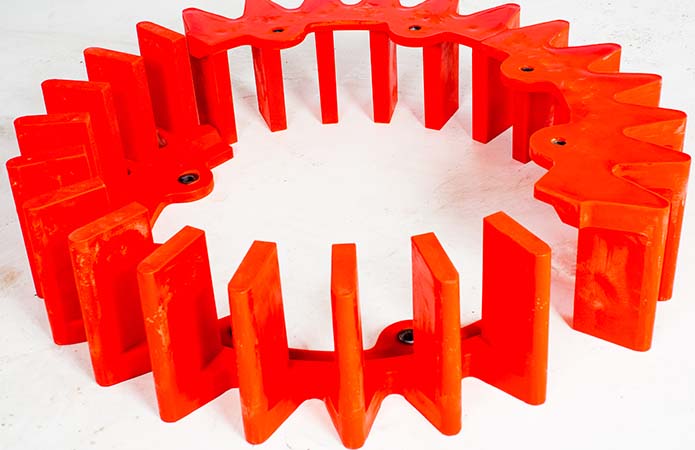

Iracore flotation equipment is manufactured using the highest quality materials available, including our proprietary polyurethane compounds. Unlike other suppliers, Iracore’s expert team of chemists, engineers, and consultants designs materials and components tailored explicitly to flotation applications.

Equipped with decades of field knowledge in the mining industry, Iracore engineers flotation wear products meet and exceed rigorous operating conditions in heavy industry. Iracore flotation wear products have a proven wear life two to three times longer than parts from other urethane and rubber manufacturers.

Industry-Leading Fit & Performance

Inferior flotation parts often fit poorly, leading to decreased product recovery. Even worse, poor design and construction often lead to premature wear, increasing operations’ maintenance, downtime and replacement costs. On the other hand, a well-fitting and durable flotation wear product will maximize your operation’s efficiency through every stage of production.

Having worked with some of the industry’s largest names as an OEM manufacturer, all Iracore flotation components are designed for 100% compatibility with nearly any equipment. Our high-quality construction ensures the highest recovery rates in the industry, while our engineered polyurethane materials last longer than any material on the market today, allowing your operation to eliminate unnecessary downtime for increased output and return on investment.

Manufacturing for Projects of All Scopes

Iracore’s state-of-the-art manufacturing facilities are capable of high-volume output, allowing us to support projects of all sizes and scopes. From Alberta’s remote Oil Sands to dredging in Europe and Asia, Iracore has the manufacturing and distribution capabilities to supply even the most remote operations. We are committed to our ISO 9001 quality management system, allowing us to deliver top-quality products for operations around the world.

Looking for Flotation Wear Products?

Contact us today to learn more about Iracore’s comprehensive range of flotation components.

Recent Comments