POLYURETHANE

POLYURETHANE

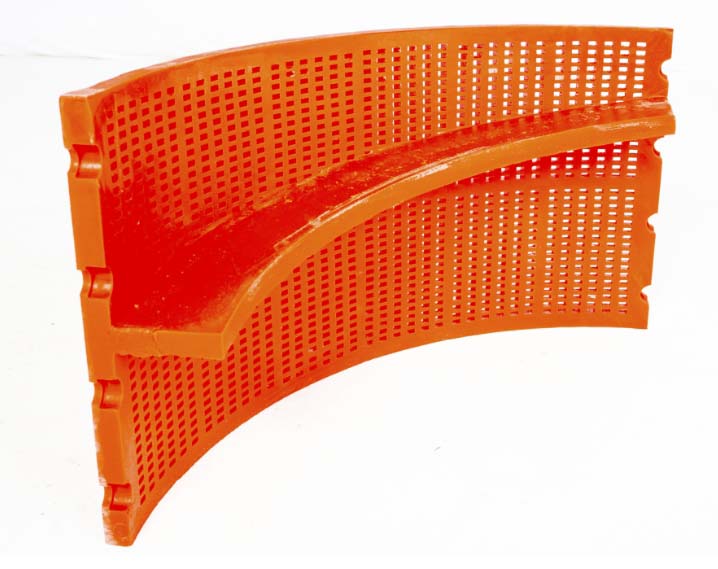

At Iracore, our polyurethane is formulated by our in-house chemists to meet the specific demand it will face in your environment.

Unlike many other urethane parts manufacturers, Iracore sources raw materials from major chemical producers to create custom polyurethanes. The polyurethane formulations have been developed through decades of field knowledge to meet rigorous operating conditions in heavy industry.

With the largest computer-controlled casting machines in North America, we can create urethane parts ranging from simple small pours (a few lbs) to the large volumes (3500lbs) required to line bore pipe up to 60’ in length.

Choice of polymer depends on the following

- Hardness and other physical property requirements

- Environmental factors (exposure to oil, water, other fluids, temperature, etc.)

- Tooling cost (injection molds vs. open cast vs. compression molds)

- Mode of failure (fatigue, cut and tear, wear, compressive loads, etc.)

Key Factors for Selecting the Proper Urethane Elastomer

- Compression or load-bearing requirements

- Slurry or service environment composition (pH)

- Temperature range

- Particle size, shape and velocity on impact abrasion

- Wet service environment and expected service life

Material Selection Guide

Material Selection Guide

Key Factors For Selecting the Proper Urethane Elastomer

Hardness

Important factor for load bearing / compression requirements

65-95 Shore A available

Not a great indicator of overall elastomer performance

Service Environment Composition

- Dry or Wet Service

- Solution pH

- Slurry particle size, shape, and velocity

Operating Temperatures

Applications across a broad range of temperatures, -80F to 93F

Performance properties vary with temperature

Abrasion Mechanism

Sliding – High toughness and high tear strength best

Impact – High resiliency best

Erosion / Corrosion – elastomers protect against most ferrous corrosion mechanisms

Operating Temperatures

Applications across a broad range of temperatures, -80F to 93F

Performance properties vary with temperature

Abrasion Mechanism

Sliding – High toughness and high tear strength best

Impact – High resiliency best

Erosion / Corrosion – elastomers protect against most ferrous corrosion mechanisms

Tooling Costs

- Open casting vs. compression vs. injection molds

Operating Temperatures

Applications across a broad range of temperatures, -80F to 93F

Performance properties vary with temperature