Rubber compounds are the most common materials found in pipe lining. Today, there are many natural and synthetic compounds suitable for nearly every industry. Neoprene (also known as chloroprene) is an excellent general-purpose rubber that performs in a wide variety of uses and applications.

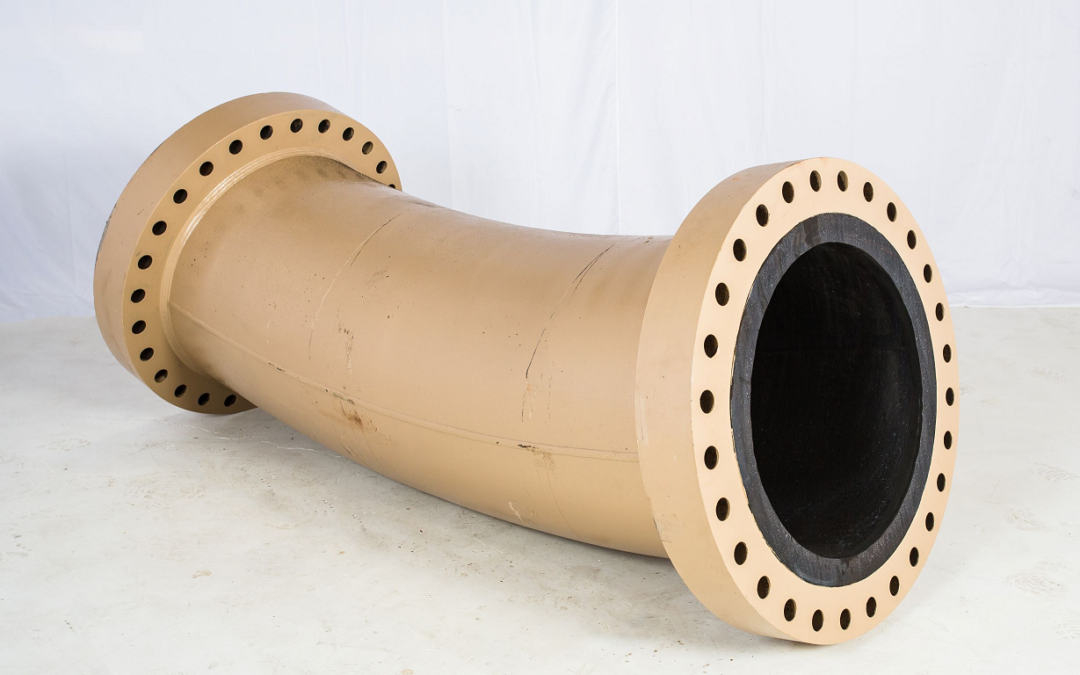

Iracore has been manufacturing and distributing rubber-lined products across North America since 1957. With over 60 years’ experience spanning numerous heavy industries, our experts can help you find the right lining compound for your operation’s slurry transport system, all while providing exceptional value and service. Read on to learn more about the benefits and applications of our neoprene-lined products below.

Rubber Products for Every Application

Neoprene is an elastomer that provides good oil, chemical, ozone, weathering and abrasion resistance. While many other rubber compounds boast substantial resistance to abrasion and weathering, they lack the chemical makeup to withstand the presence of oil or other hydrocarbons. As such, neoprene lining is an excellent choice for use in the oil and gas industry, outlasting and outperforming most other rubber-based compounds.

Neoprene-lined pipe offers numerous other advantages over other materials. First, neoprene’s elastic nature makes it resilient in high-impact, high-velocity fluid systems, such as turbulent slurry applications. Neoprene’s durability means it needs replacing less frequently, saving your operation from unnecessary downtime and replacement costs.

Next, neoprene has excellent insulative properties, meaning it can help maintain heat and temperature consistency to prevent freeze-ups, even in the most frigid conditions. Neoprene-lined pipe keeps heat inside your fluid system, leading to energy savings and lower operating costs.

Neoprene-Lined Products at Iracore

All Iracore neoprene-lined components undergo vulcanization (curing) to enhance the performance properties. With some of the largest autoclaves in the industry, Iracore can properly cure neoprene-lined pipe in lengths up to 60 feet. Our manufacturing facilities are ISO 9001-certified, ensuring that we can efficiently produce the neoprene-lined parts our customers need, when they need them. No matter the size or scope of your operation, Iracore can produce neoprene-lined products that provide excellent value and exceptional performance 100% of the time.

Need Neoprene-Lined Pipe for Your Next Project?

Contact us today to learn more about Iracore’s full range of pipe lining solutions.

Recent Comments