Today, mining operations around the globe are looking for value-adding solutions to wear challenges. Specifically, extending equipment life has the potential to save organizations thousands in maintenance, repair, and downtime. The right wear materials and components have the potential to prolong your equipment’s service life, keep your processes efficient, and keep your entire operation running smoothly.

For over 60 years, Iracore has specialized in finding innovative solutions for the mining industry’s unique wear challenges. Today, our industry-leading line of wear components deliver unrivalled durability and performance while providing exceptional value and return on investment for our clients and their stakeholders. Read on to learn more about the benefits of Iracore’s mining wear products below.

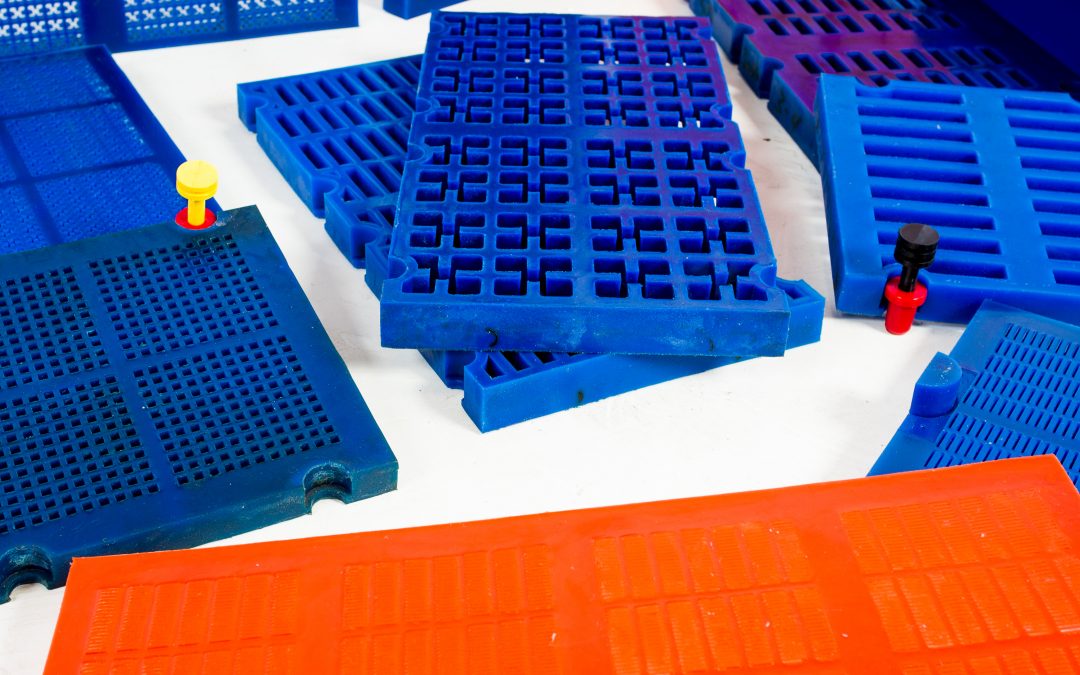

Lab-Tested, Field-Approved Wear Materials

Unlike most urethane suppliers, Iracore sources raw materials directly from chemical manufacturers to create unique compounds explicitly tailored to the unique needs of mining operations. Our research and development team is dedicated to finding solutions to every wear challenge, resulting in the best polyurethane compounds available on the market today. Decades of research and refinement have led to Iracore wear components performing exceptionally well, both in independent testing and in countless use-case scenarios.

Lining components with Iracore urethane can potentially save your operation thousands of dollars in maintenance and downtime, maximizing return on investment for you and your stakeholders. Our urethane compounds are formulated to withstand the most challenging operating environments while providing unrivalled durability and performance, allowing you to get the most out of your process equipment.

Wear Components for Your Entire Process

Iracore manufactures wear materials for a wide variety of mining process equipment, including (but not limited to):

- Crushers

- Screen Decks

- Mills

- Trommel Screens

- Cyclones

- Pumps

- Floatation

- In-Plant and Tailings Pipes

No matter what your process requires, Iracore provides a comprehensive selection of high-performance wear materials that can extend equipment life through reliable durability.

Custom Fabrication

For processes with unique wear challenges or requirements, Iracore is proud to manufacture custom wear components suited for your operation’s needs. Our manufacturing is also capable of precise made-to-order shapes by request. Choose from bolt-on, weld-on, or magnetic application methods and find the perfect fit for a wide variety of applications, including:

- Bins

- Launder Chutes

- Tanks

- Flotation Cells

- Truck Beds

- Turn Heads

- Ducts

- Conveyance Systems

- And More!

Manufacturing for Operations of All Sizes

Our industry-leading manufacturing facilities and output capacity make Iracore a leading choice for any operation. Backed by ISO 9001 certification, our stringent quality control standards ensure our customers get the high-performance wear components they need 100% of the time. No matter what your organization’s wear material needs, you can rely on Iracore to provide exceptional value and service while keeping you on the cutting edge of wear technology.

Ready to Learn More?

Contact us today to get started with Iracore’s wear products for the mining industry.

Recent Comments