Across heavy industry, rubber-based compounds remain the most popular wear materials used today. There are natural and synthetic rubbers suitable for virtually every industry, application, and process. In particular, neoprene is a versatile general-purpose rubber that works well in a variety of situations. Because of its versatility, it can be used in a wide range of processes. However, no wear material is “one-size-fits-all;” it’s essential to choose a wear material that can add value to your entire operation through optimized throughput and lower repair/maintenance costs. Learn more about the ideal uses of neoprene below, as well as Iracore’s extensive range of neoprene-lined pipe products.

Hydrocarbon Resistance

Neoprene provides an excellent balance of oil, ozone, weathering, and abrasion resistance. While many other rubbers effectively resist abrasion and weathering, they lack the chemical makeup to withstand bitumen and other hydrocarbons. Using natural gum rubber or many synthetic compounds in these applications can lead to premature wear, leading to more downtime and higher repair and maintenance costs.

While neoprene has similar chemical properties to natural and synthetic rubbers, it also includes greatly improved resistance to hydrocarbons. This makes it an ideal pipe lining material for processes involving bitumen, oil, or other hydrocarbons that also require similar properties to natural and synthetic rubbers.

High-Impact Resilience

Neoprene’s resilience makes it ideal for high-impact, high-velocity areas of any fluid process. Neoprene has superior performance characteristics compared to most rubbers in direct-hit and impingement situations, including those found in turbulent slurries. In addition to being a leading choice for pipe lining, many systems also use neoprene-lined fittings to resist wear in fitting or anywhere fluid makes a sharp, high-impact turn.

Because of its performance and longevity, neoprene has to be replaced less often, reducing downtime and repair costs.

Eliminating the Cold-Wall Effect

In addition to hydrocarbon resistance and performance in high-impact areas, neoprene has excellent insulative properties. It can help maintain heat and temperature consistency in an operation’s pipe system, preventing what’s known as the Cold Wall effect. Especially in cold conditions, neoprene-lined pipe can help prevent freeze-ups and equipment damage, minimizing downtime. Even in warmer climates, neoprene-lined pipes can maintain heat and energy within your process, leading to energy savings, lower fuel consumption, and savings on operating costs.

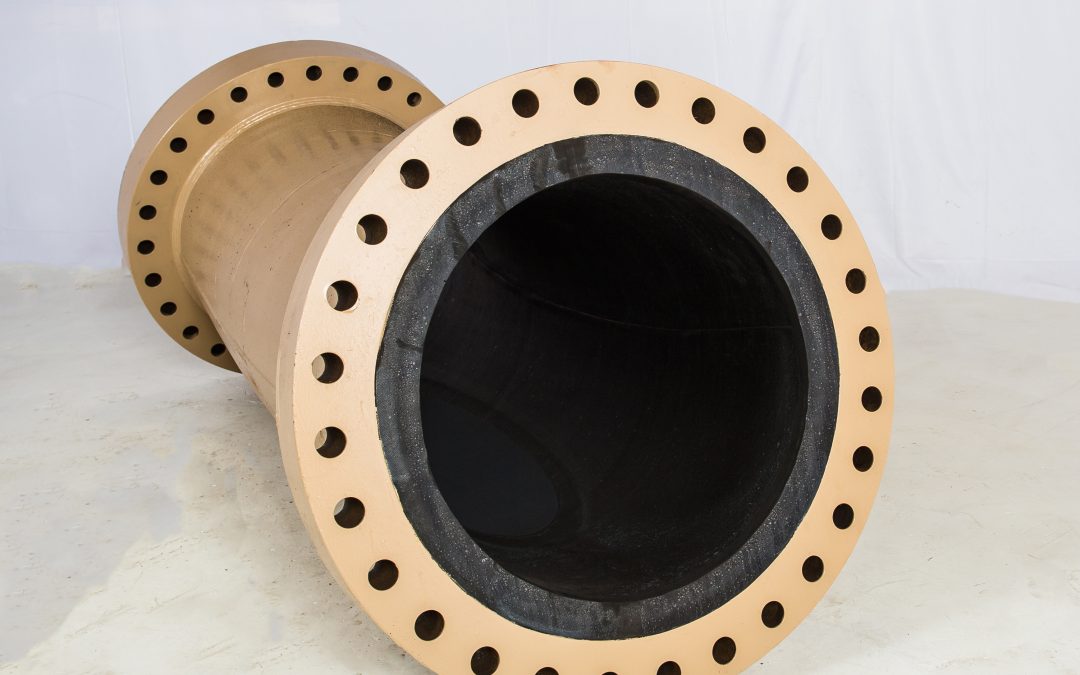

Iracore’s Neoprene-Lined Pipe

Iracore produces and distributes neoprene-lined pipe and fittings for a range of heavy industrial uses. Iracore is committed to engineering wear technologies that add value for our consumers, no matter what their process requires.

All Iracore neoprene-lined components undergo vulcanization (curing) to enhance neoprene’s performance properties. With some of the largest autoclaves in the industry, Iracore can properly cure neoprene-lined pipe in lengths up to 60 feet. Our manufacturing facilities are ISO 9001-certified, ensuring that we can efficiently produce neoprene-lined parts capable of performing in the most demanding conditions. No matter the size or scope of your operation, Iracore can produce neoprene-lined products that provide unbeatable performance and value.

Looking for Neoprene-Lined Pipe?

Contact us today to learn more about Iracore’s full range of neoprene lining solutions.

Recent Comments